NOAA, Dow Chemical Collaborate on Update to Federal Chemical Safety Software Tool

MARCH 25, 2013 — NOAA has partnered with chemical industry experts from the Dow Chemical Company to release a significant update to a free software program used to prevent dangerous chemical incidents and help protect emergency workers responding to hazardous chemical spills. The software, known as the Chemical Reactivity Worksheet, predicts potential hazards from mixing chemicals. This newest version of the program is the result of a two-year-long collaboration between NOAA chemical response specialists, technical experts at Dow, and partners at the Center for Chemical Process Safety.

"This is an innovative collaboration between industry and government scientists to produce a valuable tool that addresses reactive chemical hazards," said Jim Farr, NOAA chemist and project coordinator. "We hope this effort paves the way for other projects that enhance our understanding of chemical hazards and leads to a safer work environment for those people in the chemical industry and those that respond to chemical incidents."

"We've greatly appreciated the opportunity to partner with NOAA on this and see this as a win-win for everyone," said Dave Gorman, Dow chemist and project leader. "This collaboration has allowed us to merge a number of best practices and tools used within Dow with the very powerful Chemical Reactivity Worksheet tool. The result is a much more powerful and versatile tool that we hope will become the gold standard within industry for determining chemical compatibility."

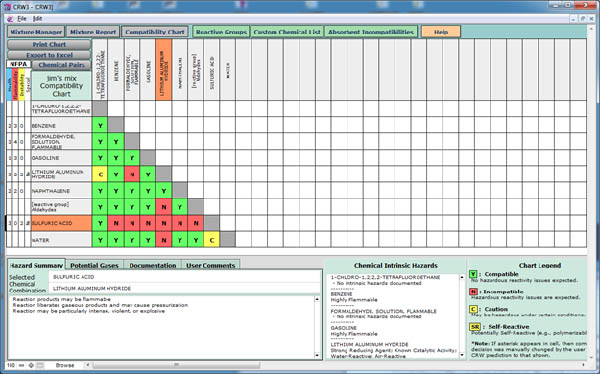

The Chemical Reactivity Worksheet provides information about 5,200 chemicals, each assigned to one or more "reactive groups" of chemicals which may react in a characteristic and potentially hazardous way if they come in contact with certain substances. The user creates a virtual mixture of chemicals—which could include the chemicals involved in a hazardous incident or stored in a laboratory, warehouse, or transport vehicle. Then the program predicts the possible hazards, including fire or explosion, from mixing all possible pairs of those chemicals.

This latest release of the software increases the number of reactive groups, allowing for more refined predictions of potential chemical reactions, and expands the description of reactive chemicals. The program now includes an alert for possible gases released from a chemical mixture, as well as information on the compatibility of common absorbents used in response to spills of hazardous chemicals. In addition, managers of chemical facilities and university chemistry departments now can add chemicals unique to their facilities, enabling them to further customize their evaluations of potential hazards. Other improvements include enhanced ease of use and functionality for the user, refined reactivity predictions, and updated chemical data.

The Chemical Reactivity Worksheet is available for download online at http://response.restoration.noaa.gov/reactivityworksheet. The work was done as part of NOAA and the U.S. Environmental Protection Agency's joint development of the CAMEO software suite, which provides valuable emergency response and planning tools for releases of hazardous materials. The Center for Chemical Process Safety also contributed to the project. The team's work was reviewed by other chemists in industry and at Argonne National Laboratory.

An official website of the United States government.

An official website of the United States government.