Ask Dr. ALOHA: Using CAMEO Tools for RMP and EPCRA Hazard Analyses, Part 2

Using ALOHA to Perform an RMP Alternative Consequence Analysis (Fictional Example)

Susan, an environmental consultant, has been asked by the manager of the River City Water Treatment Plant to help make sure that the plant is in compliance with the Risk Management Plan (RMP) rule. She has already completed the worst-case consequence analysis, and now she must also complete a consequence analysis for an alternative release scenario.

Checking Whether an Alternative Release Scenario is Required

Facilities that are subject to the RMP rule have more than a threshold quantity of a regulated substance in a vessel or process line and must complete a worst-case consequence analysis. Additionally, facilities must complete a consequence analysis for an alternative release scenario for each regulated chemical in a process that is classified as Program 2 or 3. Worst-case scenarios are explicitly defined in the RMP rule, but facilities are free to design alternative release scenarios that are more likely to occur. While completing her worst-case consequence analysis, Susan performed an inventory and found that only one process at the plant exceeded the threshold quantity for a regulated chemical. The plant maintains two 1-ton tanks of chlorine (liquefied under pressure) in an open-walled shed near the chlorination room. Both tanks connect to a single line leading into the chlorination unit. Because they're connected to the same line, she considers both tanks to be part of the same process. The amount of chlorine in this process is 2 tons (4,000 pounds) when the tanks are full, which exceeds the threshold quantity for chlorine (2,500 pounds). To determine if she needs to complete a consequence analysis for an alternative release scenario, Susan needs to verify which program the process falls under. A chemical process that is subject to the rule is classified as either Program 1, 2, or 3. Only Program 1 processes are exempt from the alternative release scenario requirement. Susan goes to the RMP guidance document to read about the three programs:

- Program 1: Processes that wouldn't affect the public in a worst-case release and that haven't had accidents with specific offsite consequences in the past five years.

- Program 2: Processes not eligible for Program 1 or subject to Program 3.

- Program 3: Processes not eligible for Program 1 and either subject to the OSHA Process Safety Management standard under federal or state OSHA programs or classified in one of ten specified North American Industrial Classification System (NAICS) codes.

Susan determines that the plant's chlorination process falls into Program 2 by process of elimination. Although the plant has never had a substantial offsite chlorine release, it can't be a Program 1 process because there are public receptors (several neighborhoods and a shopping center) within the 3.3 mile radius identified in the worst-case consequence analysis. Also, it can't be a Program 3 process; the plant's process isn't subject to the OSHA Process Safety Management standard and it isn't classified in any of the NAICS codes listed in the rule. Because the process is classified as a Program 2, Susan needs to design an alternative release scenario for the chlorine process and perform another consequence analysis.

Getting Ready to Analyze an Alternative Release Scenario

To perform her analysis, Susan can follow the procedures described in the RMP guidance document or use an air dispersion model that adheres to the parameters listed in the rule. Susan used the ALOHA hazard model to perform her worst-case consequence analysis, and she'll use it to perform her alternative consequence analysis too. To design her alternative release scenario, Susan makes use of some of the basic principles of hazard analysis (a method for systematically evaluating the hazards and risks posed by hazardous materials at a facility or other location). In a hazard analysis, you identify the places in a process where failure events might occur—that is, places where something might go wrong with a process component so that the hazardous material is accidentally released. As part of her research to identify the most likely failure events for the plant's chlorination process, Susan checks with the River City plant manager and other water treatment plant managers to find out the kinds of things that could go wrong. Susan decides that a realistic failure event would be a leak from the fill valve on one of the chlorine tanks while it is being refilled. The valve opening has a 3/4 inch diameter and is located at the top of the tank. Susan decides to assume that the leak occurs when the tank is nearly full (2,000 pounds). (Note that if you're the operator of a water treatment plant, you might make a different choice that would be better suited to your circumstances.) Additionally, she decides to use these conditions for her alternative release scenario:

- Wind speed of 6.7 miles per hour and D-class atmospheric stability, which is what the rule recommends when historical weather data is not available (as is the case for the plant's location).

- Air temperature of 98°F and 70 percent humidity, because those are the values she used in the worst-case scenario. (This is the highest daily maximum air temperature measured during the past three years and the average humidity at the plant location.)

- Urban for surface/ground roughness, because the plant is in an urban area.

- Substance's toxic endpoint, which is specified in the rule for the worst-case scenario. For chlorine, the endpoint is 0.0087 milligrams per liter or 3 parts per million. (This value is based on the ERPG-2 for chlorine.)

Note: To use ALOHA to model this alternative release scenario, Susan will also need to determine appropriate values for the additional scenario inputs that the ALOHA model requires. Susan already knows how she will enter most of these conditions, because ALOHA requires her to enter them whenever she models a scenario. However, ALOHA usually calculates the atmospheric stability class for her based on scenario conditions. To choose D-class stability, Susan knows that she has two options (because she already read the ALOHA help topic on atmospheric stability to complete her worst-case consequence analysis): (a) choose scenario conditions (time of day, cloud cover, and wind speed) that will result in D-class stability or (b) force ALOHA to use D-class stability by using the Override button. Susan decides to choose scenario conditions that are appropriate for D-class stability. The table in the stability class help topic shows that completely overcast conditions are always associated with D-class stability, regardless of whether it is day or night. Now she is ready to start entering information into ALOHA.

Making a Consequence Analysis of an Alternative Release Scenario

Susan starts ALOHA, then chooses River City from the list of locations. Because D-class stability can occur at any time, she decides to model the release assuming it occurs mid-afternoon. From the SiteData menu, she chooses Date & Time and sets the time to 14:00 (that is, 2:00 PM). Then, from the SetUp menu, Susan chooses Chemical, and selects chlorine from ALOHA's chemical library. Next, Susan goes to the SetUp menu, selects the Atmospheric submenu, then chooses User Input. The first atmospheric dialog box appears.

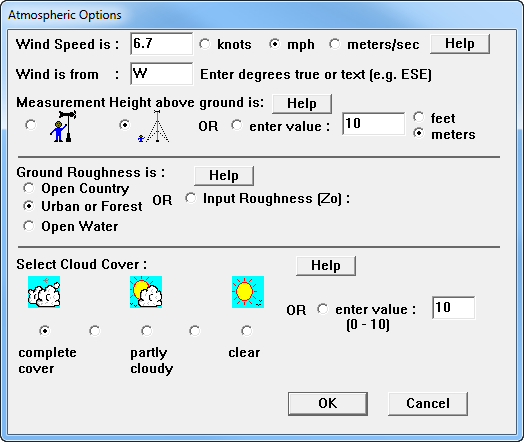

This is how Susan completes the first atmospheric dialog box:

- Wind Speed: 6.7 miles per hour, because it is suggested in the RMP rule.

- Wind Direction: West. The direction of the wind doesn't matter in this case (because Susan only needs the distance to the toxic endpoint), so she arbitrarily picks west.

- Wind Measurement Height: 10 meters, because wind speed is typically measured at that height.

- Ground Roughness: Urban or Forest, because the plant is in an urban area.

- Cloud Cover: Complete cover, because that is appropriate for D-class stability.

When she finishes, a second atmospheric dialog box appears.

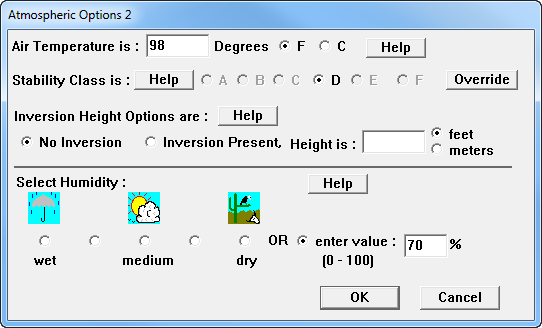

This is how Susan completes the second atmospheric dialog box:

- Air Temperature and Humidity: 98°F and 70% humidity, because she used these values in the worst-case scenario.

- Inversion Height: No Inversion, because the type of low-level inversions that can affect ALOHA's threat estimates are rare.

- Stability Class: Susan notes that her scenario conditions were appropriate and ALOHA has selected D-class stability, so she does not need to override the selection.

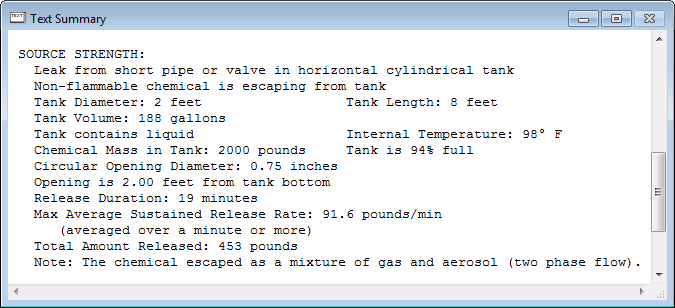

Susan is now ready to set the release source. The alternative release scenario involves the release of chlorine from a valve in a tank that contains 2,000 pounds of chlorine. In ALOHA, this release can be modeled using the Tank Source option. From the SetUp menu, Susan selects the Source submenu, then chooses Tank. This is how she completes the Tank Source dialog boxes:

- Tank Size and Orientation: She selects horizontal cylinder (because the tanks are stored lying on their sides) and enters the dimensions of the chlorine tank: a diameter of 2 feet and a length of 8 feet.

- Chemical State and Temperature: She selects "Tank contains liquid" and "Chemical stored at ambient temperature" because the chlorine is stored as a pressurized liquid at ambient temperature.

- Liquid Mass or Volume: She enters 2,000 pounds as the mass of chlorine in the tank, based on a conservative assumption that the tank is nearly full when the leak occurs.

- Area and Type of Leak: She describes the leaking fill valve by selecting circular opening, entering an opening diameter of 3/4 inches, and then selecting short pipe/valve.

- Height of the Tank Opening: She enters 100% of the way to the top of the tank to describe the height of the leak opening in the tank, because the fill valve is on the top of the tank.

Once she clicks OK, ALOHA estimates the source strength for this scenario.

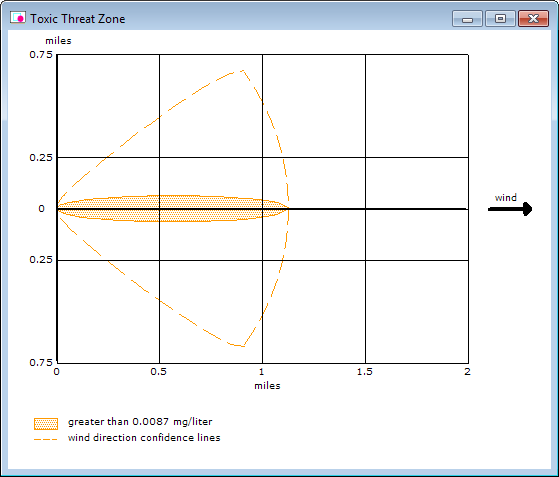

Susan notes that ALOHA predicts that less than 500 pounds of chlorine will be released, even though there were 2,000 pounds in the tank. This is because auto-refrigeration (the drop in temperature inside the tank as the chemical vaporizes) effectively stops the release when the temperature drops to the boiling point of chlorine. Next, the rule specifies that the model must appropriately account for gas density, which ALOHA does by default. However, just to be sure, she chooses Calculation Options from the SetUp menu and verifies that "Let ALOHA decide" is selected. She knows that when this default option is selected, ALOHA will assess whether a gas is dense (heavier than air) or neutrally buoyant, and will model it accordingly. Now Susan is ready to obtain the distance to the toxic endpoint specified in the RMP rule. From the Display menu, she chooses Threat Zone. When ALOHA prompts her for Levels of Concern (LOCs), she enters 0.0087 milligrams per liter as the user-specified Orange Threat Zone LOC and sets the other LOCs to None. (Alternately, she could have chosen the ERPG-2 level from ALOHA's list of LOCs for chlorine.) ALOHA displays a threat zone estimate for this alternative release scenario, as shown below.

ALOHA predicts a threat zone length of 1.1 miles. In RMP terminology, this is the distance to the toxic endpoint for this scenario. This is a substantially shorter distance than the worst-case threat zone length of 3.3 miles. However, the chlorine tanks are 100 yards away from the fence around the treatment plant, so Susan can see that in this alternative release the chlorine concentrations are still predicted to exceed the toxic endpoint well beyond the plant's fence. The final step in Susan's alternative consequence analysis is to check within a circle 1.1 miles in radius and centered on the treatment plant to identify the public receptors (such as neighborhoods, schools, and shopping areas) and environmentally sensitive areas that would be affected by the release. The RMP rule describes how she should do this. Susan can also choose to analyze more alternative release scenarios if she wishes. She might decide to do this if she felt that analyzing additional releases would help her and the plant manager better understand the hazards posed by the chlorination process, or if she felt that additional analyses would be helpful in communications with emergency responders or the public. To complete the RMP requirements for the facility, the facility will need to include the worst-case and alternative consequence analyses in a risk management plan and submit it to the Environmental Protection Agency (EPA). For more information, see the EPA's RMP guidance documents. Questions: Contact us with questions, comments, or suggestions about ALOHA. Go back to the Ask Dr. ALOHA overview.

An official website of the United States government.

An official website of the United States government.